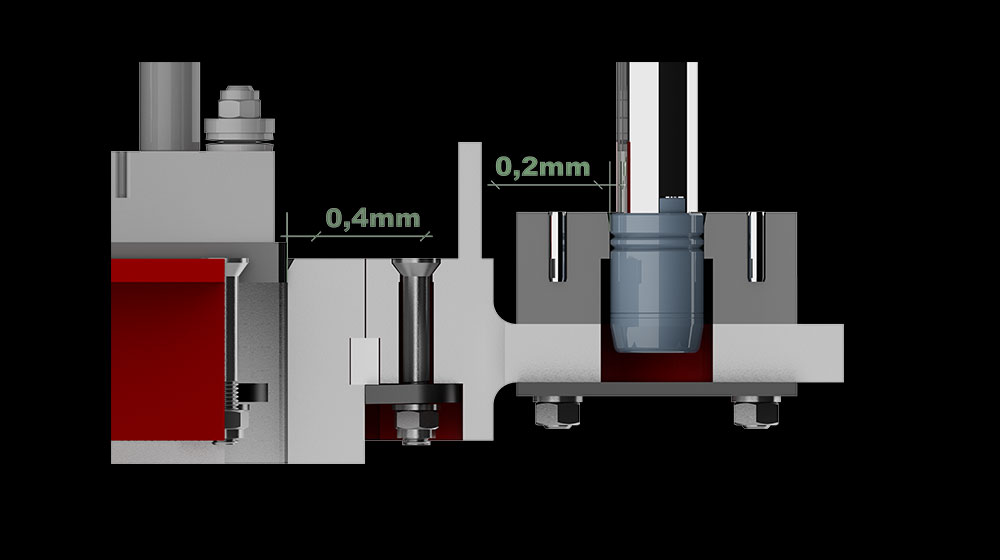

The guide pins of the positive centering system ensures precise insertion of the tamper head into the mold bottom. With an all-round clearance of two tenths mm, the mold can move freely, but remains guided at all times. Wear of the tamper shoes and the top edge of the mold is minimized significantly and the metal abrasion is almost completely prevented in the mold.

Facts & Advantages:

- All-round clearance of 0,4 mm

- All-round HeadguideTM clearance of 0,2 mm

- mold bottom freely moveable

- fixed tamperhead

- mold centering before shoes dive into the cavity

- shoes never touch mold walls

- visual wear control on pin by means of grooves 0,1 mm and 0,2 mm

Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically.

Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically. The mold bottom of a POWER »Moduline 2™«- mold is made up of only three components – the insert, the flanges and the wear plates.

The mold bottom of a POWER »Moduline 2™«- mold is made up of only three components – the insert, the flanges and the wear plates. On the outsides of a POWER »Dynamic 1™« mold there are all round trapeziums, via which the vibrating insert is clamped in bolted frame elements by means of a rubber bearing.

On the outsides of a POWER »Dynamic 1™« mold there are all round trapeziums, via which the vibrating insert is clamped in bolted frame elements by means of a rubber bearing. The POWER »Boltline 3™« is used for the production of paver and slab systems from 300mm edge length.

The POWER »Boltline 3™« is used for the production of paver and slab systems from 300mm edge length. POWER »Basicline 1™« is the classic mold for the production of medium and high paving products.

POWER »Basicline 1™« is the classic mold for the production of medium and high paving products. POWER »Boltline 1™« is used for all high products, such as hollow block, solid block, curb and round curb molds.

POWER »Boltline 1™« is used for all high products, such as hollow block, solid block, curb and round curb molds. The mold bottom of the POWER »Basicline 2™« comprises a precisely machined mold insert made of block material with all-round cavities shaped to hold the flange assemblies including rails.

The mold bottom of the POWER »Basicline 2™« comprises a precisely machined mold insert made of block material with all-round cavities shaped to hold the flange assemblies including rails.