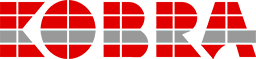

The frame elements are arranged around the insert in the bottom mold as a classic welded assembly. The mold insert is completely welded and nitrate hardened. The FORM »Optimill nitroTM« completely levels out welding stresses in the insert and increases the mold’s dynamic loading resilience.

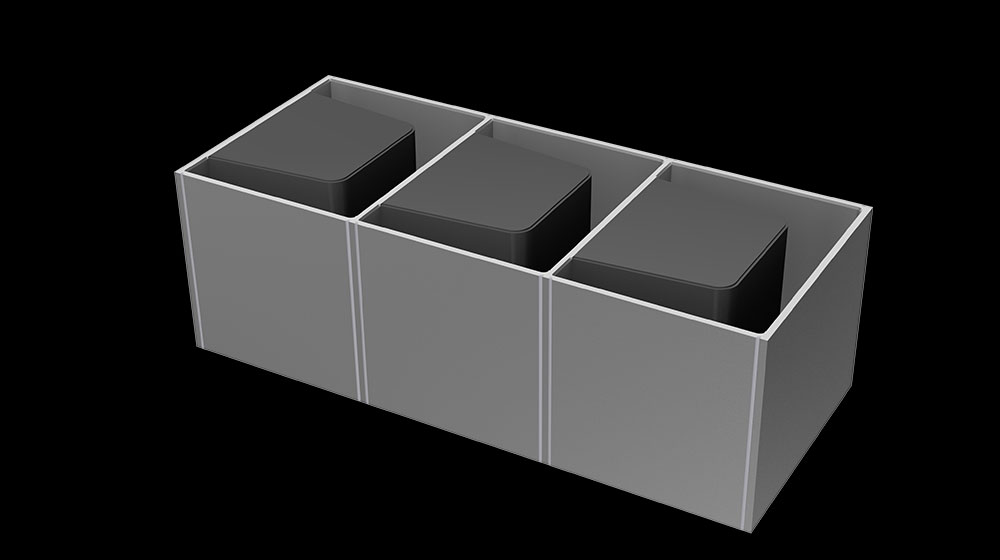

Facts & advantages:

- Maximum mold accuracy due to internal KOBRA quality standard

- Suitable for all product heights above 140 mm

- Homogeneous hardness depth 0.6 mm

- Hardness quality up to 700 HV10, hardness depth up to 0.6 mm

Hollow blocks and foundation blocks combine high stability and solidity with low weight. Fixed joints are produced, which satisfy high structural standards.

Hollow blocks and foundation blocks combine high stability and solidity with low weight. Fixed joints are produced, which satisfy high structural standards. Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block?

Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block? Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.

Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.