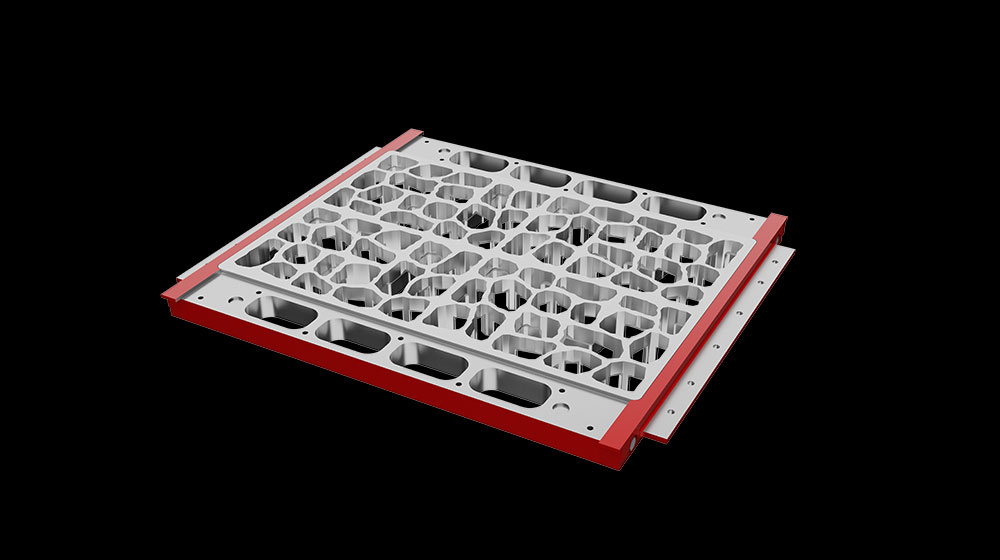

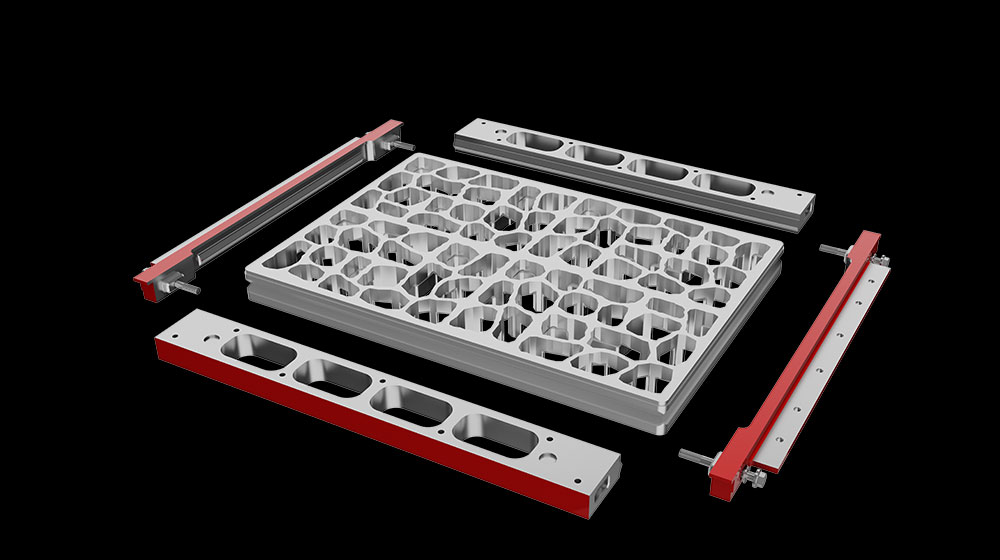

This technology enables defined vibration behavior, in which the vibration is transferred directly and effectively into the insert. In the compaction process, only the mass of the insert is accelerated and thus improved force transfer into the concrete is achieved. The improved vibration area is advantageous, especially for the production of flat products that are difficult to fill.

Facts & advantages:

- Maximum mold accuracy due to internal KOBRA quality standard

- Modular concept with individually replaceable wear parts

- Higher cost efficiency through reuse of the frame

- Increased strength of the block compared to standard molds

Permeable (or drainage) pavers are characterized in particular by their ability to allow rainwater to quickly infiltrate the pavement surface into the soil. The wide joint pattern compared to other paved surfaces enhances water percolation enormously.

Permeable (or drainage) pavers are characterized in particular by their ability to allow rainwater to quickly infiltrate the pavement surface into the soil. The wide joint pattern compared to other paved surfaces enhances water percolation enormously. Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block?

Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block?