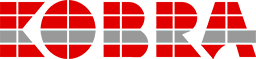

The insert is made from individual walls, which are pinned and bolted together and can be independently replaced in case of repair. The four-piece frame is also mounted around the insert with bolted joints and can be reused when replacing wearing parts. The wear plates can also be easily replaced with this system.

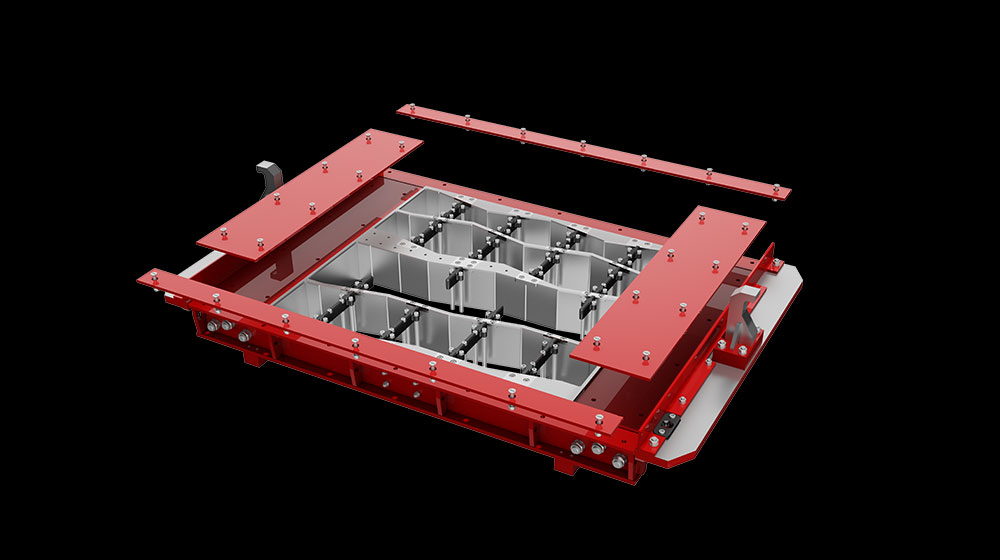

For hollow block molds the modular concept is implemented up to the core assembly. It is made up of individual elements bolted together. If one core is defective, it can be replaced without major effort.

Facts & advantages:

- Maximum mold accuracy due to internal KOBRA quality standard

- Modular concept for greater flexibility and cost efficiency in your production

- Fitted and bolted joints for targeted replacement of wearing parts

- Continuous hardness structure without weld

- High degree of mold accuracy and low wear due to FORM »Optimill carbo™« and FORM »Optimill carbo 68 plus™«

Curbs primarily have functional properties for their use as strict separation of areas with different vertical alignments. At the same time, they can be produced with project-specific color and format.

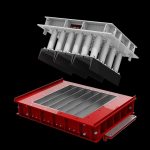

Curbs primarily have functional properties for their use as strict separation of areas with different vertical alignments. At the same time, they can be produced with project-specific color and format. Hollow blocks and foundation blocks combine high stability and solidity with low weight. Fixed joints are produced, which satisfy high structural standards.

Hollow blocks and foundation blocks combine high stability and solidity with low weight. Fixed joints are produced, which satisfy high structural standards. Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block?

Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block? Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.

Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.