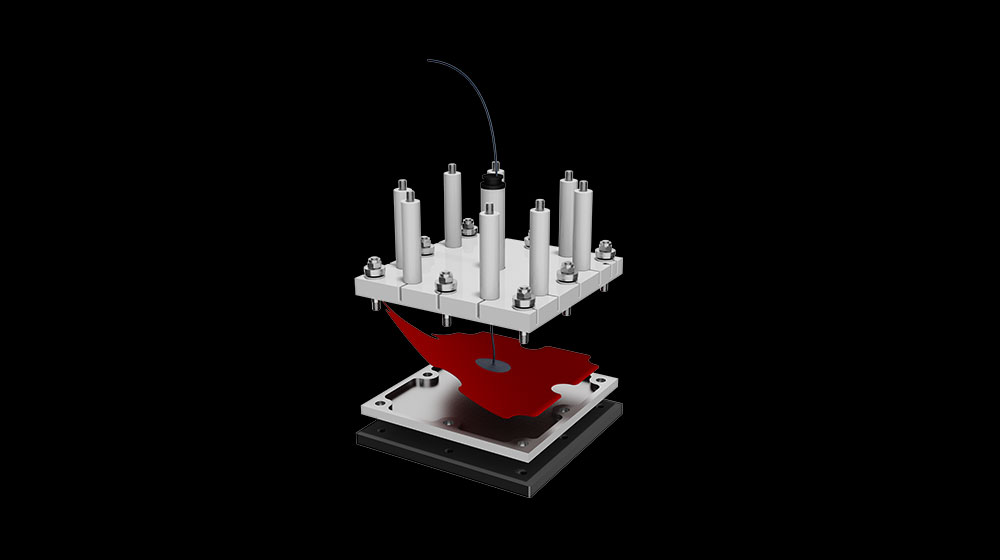

The drying of the facing concrete prevents the tamper shoes from adhering to the concrete and helps with the texture of the block surface. In this sense, the »Hotshoe™« FEATURE is an ideal demolding aid. The control compares the TARGET temperature with the ACTUAL value measured on the heating element and if necessary, reheats. The TARGET value to be set depends on the respective mold, the water ratio in the concrete mix and the ambient temperature. As a result, the water-cement content matched to the product can be used without limitation due to surface problems, since adhesion to the tamper shoes is prevented. Higher surface qualities and a refined finished surface appearance are achieved.

Facts & Advantages:

- Verifiably higher surface quality on the concrete block, fewer rejects

- The temperature range with the KOBRA control device can be controlled for customer-specific and individual product needs

- Prevents the adhesion of moist, fine facing concrete through controlled setting

- Shorter cycle times for products requiring intensive cleaning

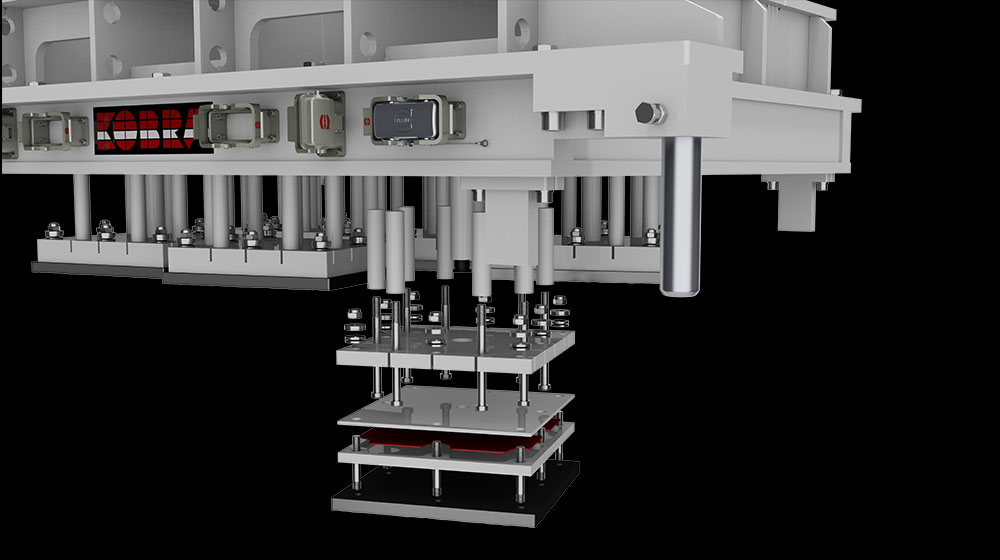

KOBRA developed the POWER »Solidline 1™« for products such as slope stabilization blocks.

KOBRA developed the POWER »Solidline 1™« for products such as slope stabilization blocks.  Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically.

Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically. The mold bottom of a POWER »Moduline 2™«- mold is made up of only three components – the insert, the flanges and the wear plates.

The mold bottom of a POWER »Moduline 2™«- mold is made up of only three components – the insert, the flanges and the wear plates. On the outsides of a POWER »Dynamic 1™« mold there are all round trapeziums, via which the vibrating insert is clamped in bolted frame elements by means of a rubber bearing.

On the outsides of a POWER »Dynamic 1™« mold there are all round trapeziums, via which the vibrating insert is clamped in bolted frame elements by means of a rubber bearing. The POWER »Boltline 3™« is used for the production of paver and slab systems from 300mm edge length.

The POWER »Boltline 3™« is used for the production of paver and slab systems from 300mm edge length. POWER »Basicline 1™« is the classic mold for the production of medium and high paving products.

POWER »Basicline 1™« is the classic mold for the production of medium and high paving products. POWER »Boltline 1™« is used for all high products, such as hollow block, solid block, curb and round curb molds.

POWER »Boltline 1™« is used for all high products, such as hollow block, solid block, curb and round curb molds. The mold bottom of the POWER »Basicline 2™« comprises a precisely machined mold insert made of block material with all-round cavities shaped to hold the flange assemblies including rails.

The mold bottom of the POWER »Basicline 2™« comprises a precisely machined mold insert made of block material with all-round cavities shaped to hold the flange assemblies including rails.