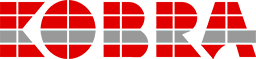

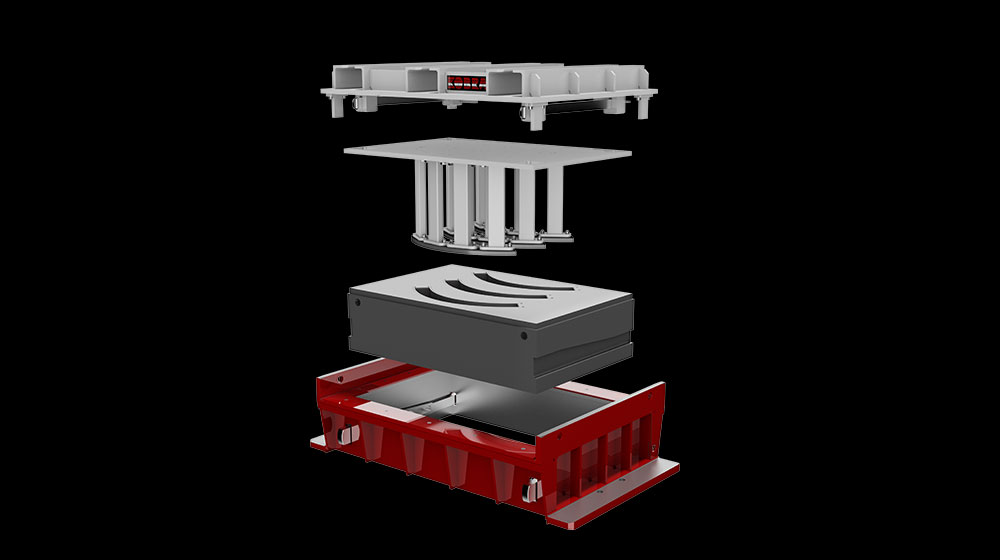

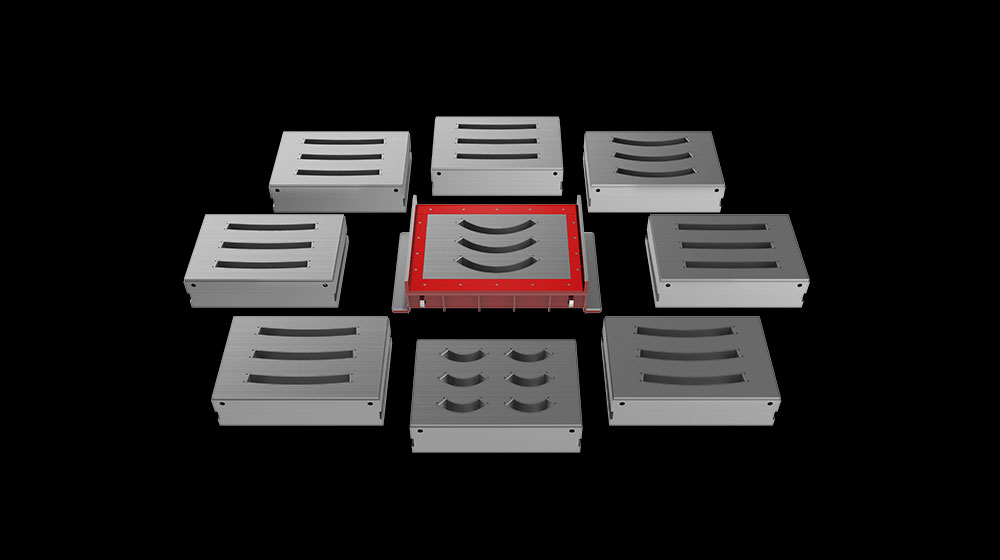

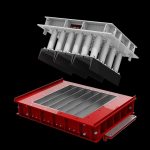

It is possible to switch between different inserts easily and in next to no time, since the locking is achieved completely without bolts. This technology assists flexible production planning and offers a large potential for time and cost savings in the project-based production of block systems.

Facts & advantages:

- Maximum mold accuracy due to internal KOBRA quality standard

- Project-based production of small series

- Modular concept with individually replaceable wearing parts

- Higher cost efficiency through reuse of the frame

Curbs primarily have functional properties for their use as strict separation of areas with different vertical alignments. At the same time, they can be produced with project-specific color and format.

Curbs primarily have functional properties for their use as strict separation of areas with different vertical alignments. At the same time, they can be produced with project-specific color and format. Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block?

Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block? Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.

Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.