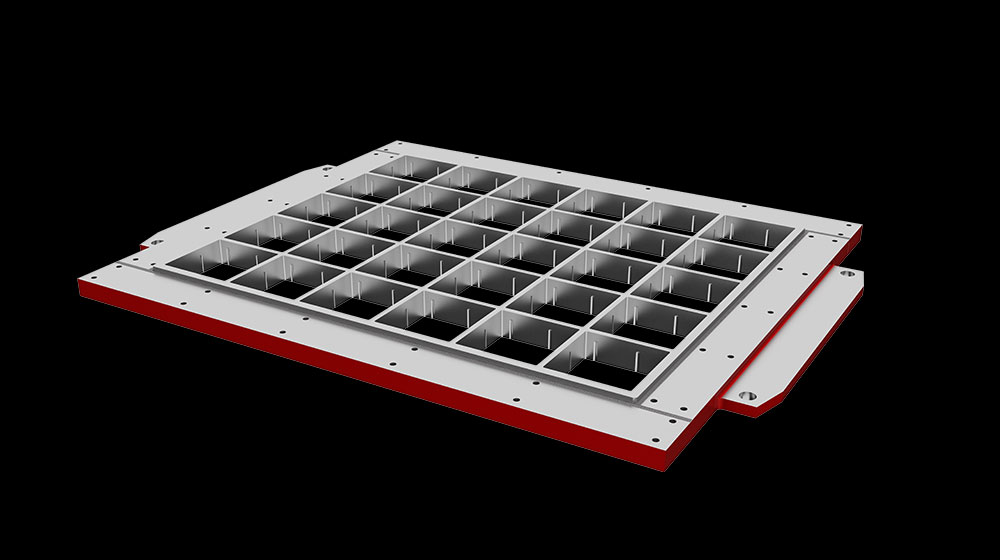

We help you early in the product development phase to develop specific products from your ideas and bring together design and function in your paving system. We produce installation pattern options, check packageability and stackability as well as the capability to manufacture the block using KOBRA mold technology.

Our sales team will be pleased to advise you on possible production options for your paver products as well as useful additional features.