The disadvantages of conventionally flame-cut molds are eliminated by the carbo hardening process, which doubles the protective effect of the mold casing by an all-round hardness depth of 1.2mm.

Facts & Advantages:

- Highest quality standard for hardness and wear resistance through further development of the carbo hardening process

- Hardness quality 68 HRC

- Homogeneous hardness depth 1.2mm

- Suitable for rustic briquet and tumbled pavers

Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically.

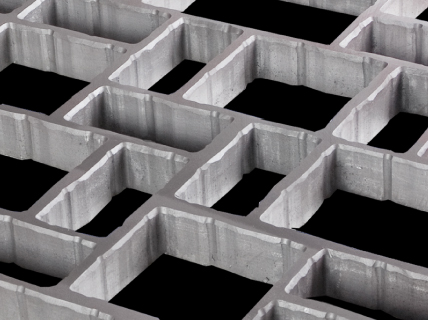

Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically. The mold bottom of a POWER »Moduline 2™«- mold is made up of only three components – the insert, the flanges and the wear plates.

The mold bottom of a POWER »Moduline 2™«- mold is made up of only three components – the insert, the flanges and the wear plates.