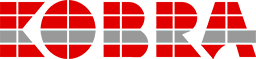

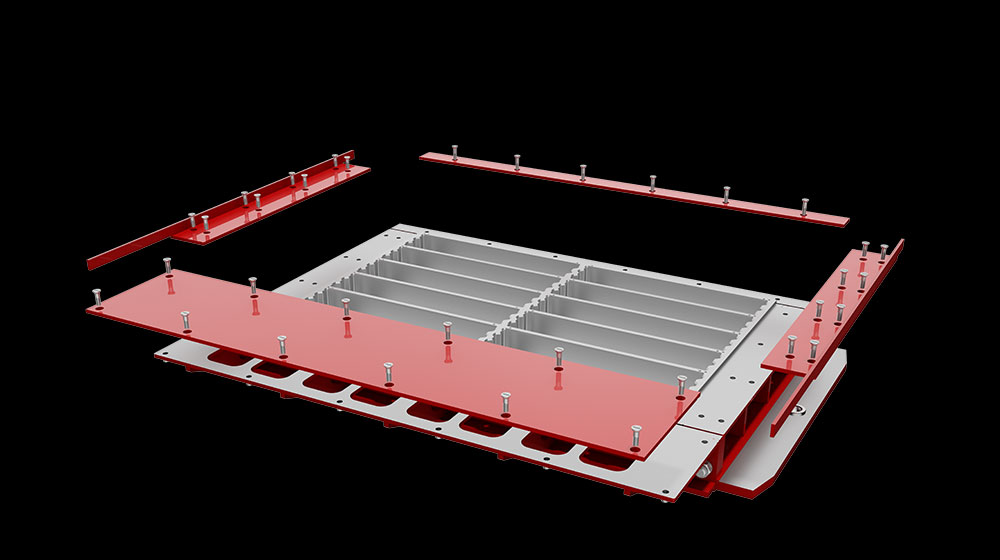

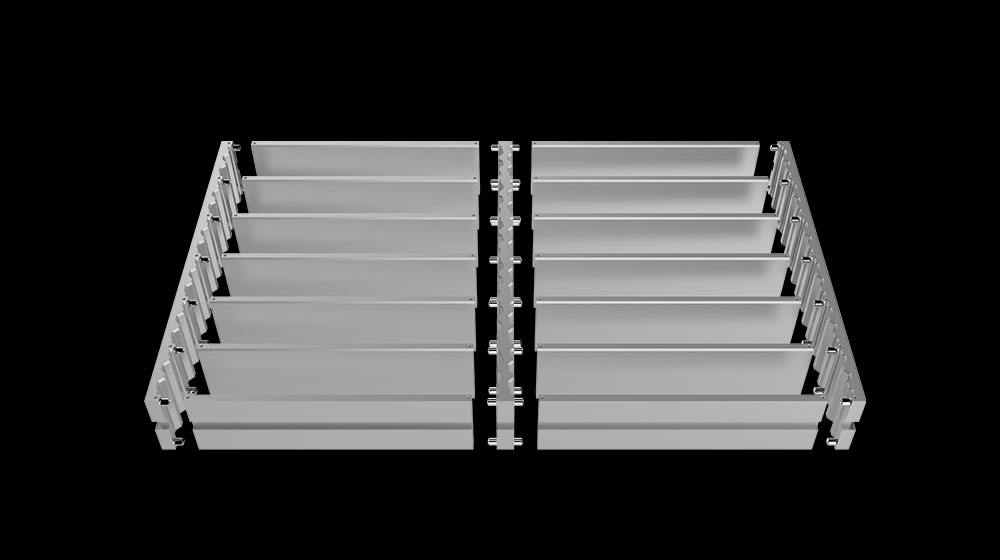

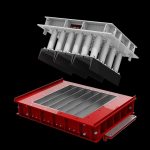

The mold inserts allow for the individual walls to be joined using bolts. All inserts are completely milled and therefore have exact angularity in the cavity with a surface hardness of 68 HRC and a homogeneous hardness depth of 1.2 mm. The smallest diagonal, straightness and angularity tolerances can be achieved, which are below the limits set by German DIN and European EN standards. POWER »Boltline 3TM« inserts can be combined with POWER »Moduline 1TM«, POWER »Moduline 3TM« and POWER »Dynamic 1TM« frames.

Facts & advantages:

- Maximum mold accuracy due to internal KOBRA quality standard

- Suitable for different insert types, such as straight or mixed layouts

- Frame bolted and reusable

- Smaller angularity and straightness tolerances and deviation of the edges than required in DIN 1339/1338.

- Replaceable wear plates bolted onto the mold frame

Curbs primarily have functional properties for their use as strict separation of areas with different vertical alignments. At the same time, they can be produced with project-specific color and format.

Curbs primarily have functional properties for their use as strict separation of areas with different vertical alignments. At the same time, they can be produced with project-specific color and format. Hollow blocks and foundation blocks combine high stability and solidity with low weight. Fixed joints are produced, which satisfy high structural standards.

Hollow blocks and foundation blocks combine high stability and solidity with low weight. Fixed joints are produced, which satisfy high structural standards. Large format concrete slabs combine modern architectural appearance and function, since they combine generously sized surface area design in conjunction with a small proportion of joints, high resilience and durability.

Large format concrete slabs combine modern architectural appearance and function, since they combine generously sized surface area design in conjunction with a small proportion of joints, high resilience and durability. Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block?

Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block? Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.

Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.