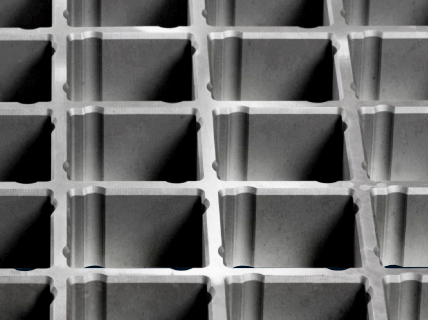

With »Optimill carbo™« the concrete block mold is equipped with a surface hardness of 62+2/-0 HRC and an all-round hardness depth of 1.2mm. In this way we achieve twice the protective effect against wear of the mold insert compared to standard molds, and thus help to achieve an economic production process in the precasting plant.

Facts & Advantages:

- Hardness, dimensional accuracy and wear resistance due to the carbo hardening process

- Cavity tolerances +/- 0.3mm

- Hardness quality 62+2/-0 HRC

- Homogeneous hardness depth 1.2mm

- Cost efficiency due to long service life

KOBRA developed the POWER »Solidline 1™« for products such as slope stabilization blocks.

KOBRA developed the POWER »Solidline 1™« for products such as slope stabilization blocks.  Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically.

Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically. The mold bottom of a POWER »Moduline 2™«- mold is made up of only three components – the insert, the flanges and the wear plates.

The mold bottom of a POWER »Moduline 2™«- mold is made up of only three components – the insert, the flanges and the wear plates. On the outsides of a POWER »Dynamic 1™« mold there are all round trapeziums, via which the vibrating insert is clamped in bolted frame elements by means of a rubber bearing.

On the outsides of a POWER »Dynamic 1™« mold there are all round trapeziums, via which the vibrating insert is clamped in bolted frame elements by means of a rubber bearing. The POWER »Boltline 3™« is used for the production of paver and slab systems from 300mm edge length.

The POWER »Boltline 3™« is used for the production of paver and slab systems from 300mm edge length. POWER »Basicline 1™« is the classic mold for the production of medium and high paving products.

POWER »Basicline 1™« is the classic mold for the production of medium and high paving products. POWER »Boltline 1™« is used for all high products, such as hollow block, solid block, curb and round curb molds.

POWER »Boltline 1™« is used for all high products, such as hollow block, solid block, curb and round curb molds. The mold bottom of the POWER »Basicline 2™« comprises a precisely machined mold insert made of block material with all-round cavities shaped to hold the flange assemblies including rails.

The mold bottom of the POWER »Basicline 2™« comprises a precisely machined mold insert made of block material with all-round cavities shaped to hold the flange assemblies including rails.