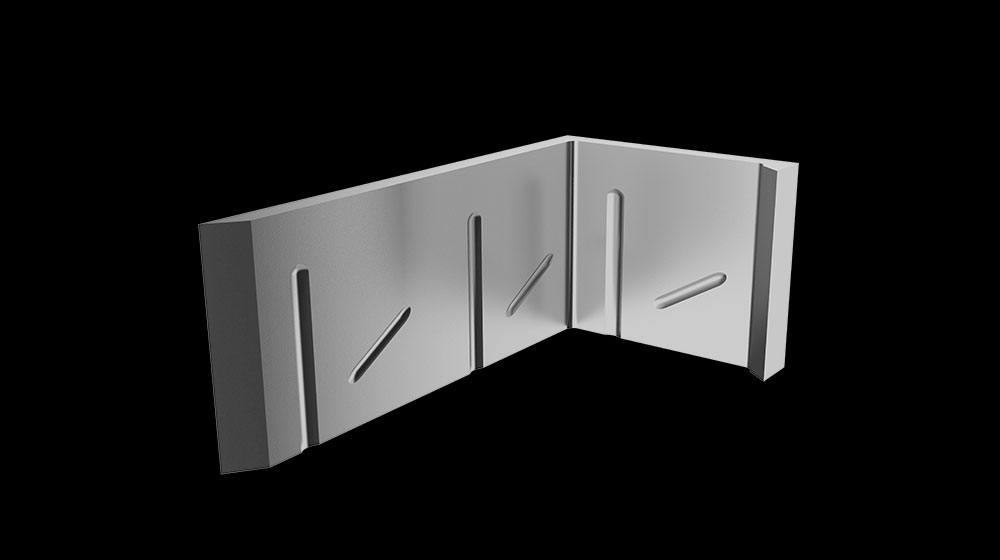

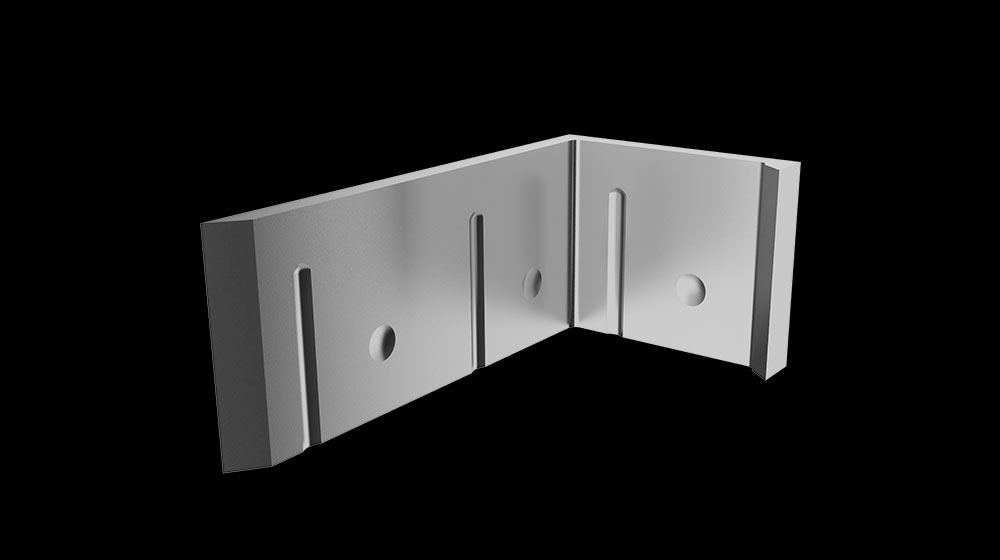

There are four standard options available to choose from, depending on the block dimensions. Inquire about individual holding systems. »Multigroove1™« describes the classic all round groove in the cavity. »Multigroove2™« is characterized by its inclined holding grooves. »Multigroove3™« describes point holding grooves »Multigroove4™« is a negative tapered cavity with holding grooves. The tapering of the block cavities fixes the blocks in the mold. The mold walls remain smooth and ensure perfect demolding performance.

Facts & Advantages:

- improved retention of the stones in the concrete block mold until the demolding process

- can also be used with draw-plates and products with bottom profiling

- product-specific retention systems

KOBRA developed the POWER »Solidline 1™« for products such as slope stabilization blocks.

KOBRA developed the POWER »Solidline 1™« for products such as slope stabilization blocks.  Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically.

Unlike the other design options of this technology, POWER »Moduline 3™« has a stable one-piece frame, which is bolted onto the insert vertically. POWER »Boltline 1™« is used for all high products, such as hollow block, solid block, curb and round curb molds.

POWER »Boltline 1™« is used for all high products, such as hollow block, solid block, curb and round curb molds. The mold bottom of the POWER »Basicline 2™« comprises a precisely machined mold insert made of block material with all-round cavities shaped to hold the flange assemblies including rails.

The mold bottom of the POWER »Basicline 2™« comprises a precisely machined mold insert made of block material with all-round cavities shaped to hold the flange assemblies including rails.