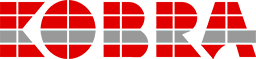

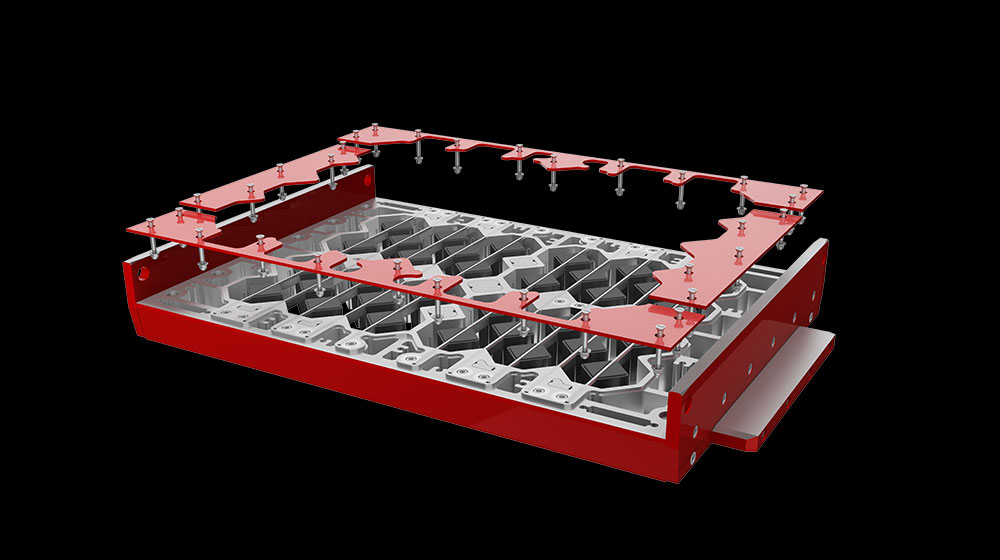

The flange assemblies are individually connected to the insert horizontally by means of shoulder screws. To prevent interruption of the insert’s hardening process with 68 HRC, it also has a special all-round cavity geometry, which is located between the block cavities and the frame elements. The tempered wear plates in the FORM »Optimill carbo 68 plus™« quality are also bolted onto the bases of the empty cavities and can be replaced easily. The flange assembly can be reused many times.

Facts & advantages:

- Maximum mold accuracy due to internal KOBRA quality standard

- Modular concept enables replacement of wearing parts

- Higher cost efficiency through reuse of the frame and flange assemblies

- Insert and wear plates in FORM »Optimill carbo 68 plus™« quality

Pavers are completely customizable in terms of format, surface texture, installation pattern and coloring and at the same time must satisfy the highest loading capacity, slip resistance, noise mitigation or water infiltration standards.

Pavers are completely customizable in terms of format, surface texture, installation pattern and coloring and at the same time must satisfy the highest loading capacity, slip resistance, noise mitigation or water infiltration standards. Permeable (or drainage) pavers are characterized in particular by their ability to allow rainwater to quickly infiltrate the pavement surface into the soil. The wide joint pattern compared to other paved surfaces enhances water percolation enormously.

Permeable (or drainage) pavers are characterized in particular by their ability to allow rainwater to quickly infiltrate the pavement surface into the soil. The wide joint pattern compared to other paved surfaces enhances water percolation enormously. Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block?

Particular projects require individual solutions. Do you need curbs with vertical and horizontal displacement protection, large format systems with false joints or contours in the underside of the block? Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.

Wall and soil retention blocks can be used for multifunctional purposes and are of central importance both in private and public spaces as design and functional elements.